RFID AGV Navigation Position Tag

The automatic guided vehicle (AGV) can accurately drive on a certain path to avoid obstacles in an unmanned environment by autonomous navigation and location. Nowadays, AGV RFID tag is widely applied to automated warehousing, factory material transfer systems, logistics picking systems, flexible assembly systems, and other intelligent transportation sites.

The idea is to use Robot RFID navigation tag placed in a grid pattern on ground. The robot contains a “map” of the Modex RFID tag ID numbers. and using this number knows where it is on the map.

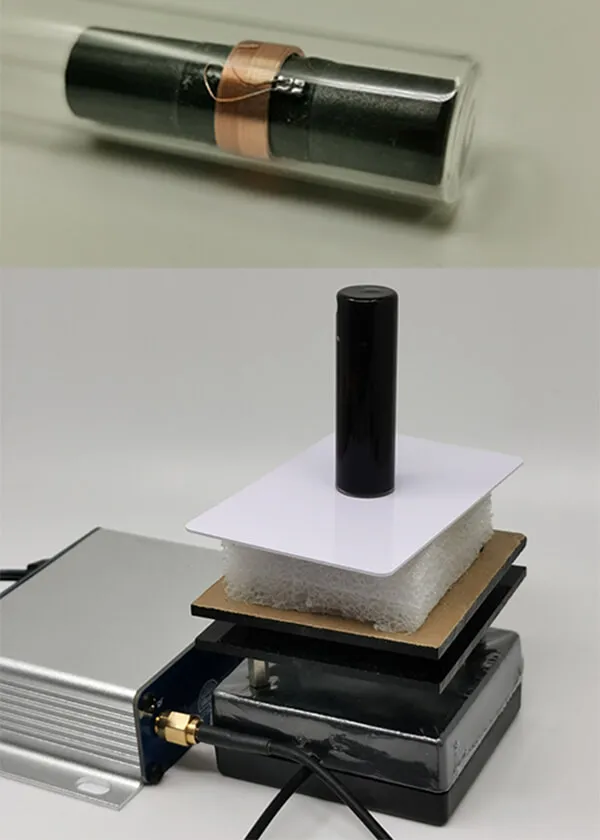

Key Feature of RFID HDX Glass Tag

- Outstanding performance in Harsh environment

- Accuracy, Repeat-ability, Flexibility, Block Stacking, Floor sub-structure, Traffic pattern

- ISO 11784/11785 full identification data programmable, BDE format

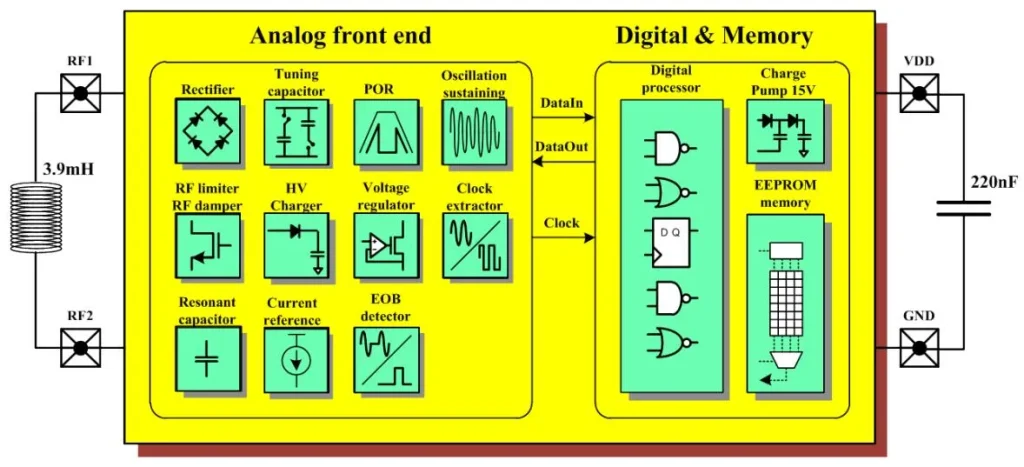

- 2 kHz, 192 Bits, Multi Purpose R/W HDX RFID IC

- Standard and advanced animal R/W RFID transponder tags

- Long read range transponder

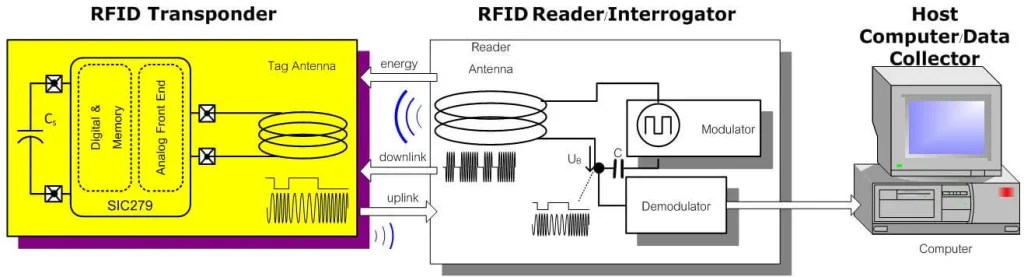

- Half duplex (HDX) 134.2 kHz contactless read/write data

- Compatible with TI RFID reader

- Write standard animal ID or write 64 bits hexadecimal value (through our reader with specified firmware and software)

- On-chip tunable resonant capacitor controlled by non-volatile memory switch

- Available in HDFN package, fully compatible with its predecessor

Applications of RFID AGV Tag

- Robotic lifter, container lifter path tracking

- Automated warehousing

- Factory material transfer systems

- Logistics pickingand flexible assembly systems

- Intelligent transportation sites

Specification of Robust AGV RFID Tag

| Item name | RFID AGV Tag |

| Protocol standard | HDX ISO 11784/11785, ICAR compliance |

| Memory | 192bit |

| Functionality | read/write |

| Frequency | 134.2 kHz |

| Typical reading range | 90mm – 120mm (desktop reader) > 30cm (reader with big antenna) |

| Weight | approx. 19g |

| IP Class | IP68 |

| Operating temperature | –25°C to 85°C |

| Write endurance | > 100,000 R/W cycles |

| Memory retention | 20 years |

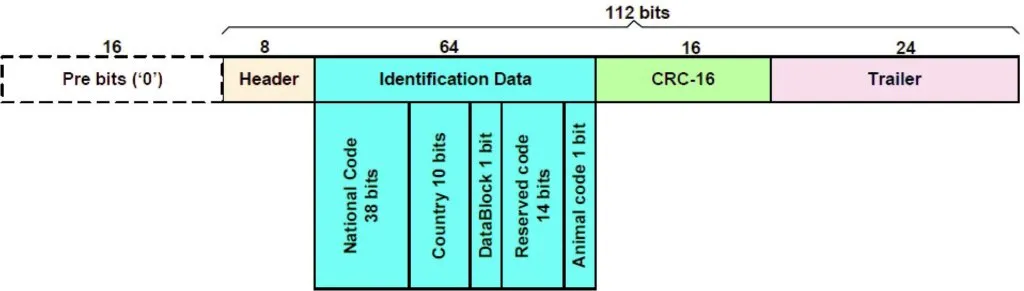

RFID Navigation Tag Supported Protocols

- Compliant with BDE format (for waste management application)

- Fully compliant with ISO 11784/11785 HDX R/O Animal tag

- ID data protocol/structure

- Fully compliant with mainstream HDX R/W ID format

Robust AGV RFID Tag Memory

- R/W user memory of 6X32 (192 bits)

- Supporting user access to factory unique ROM ID (UID), preventing chips from cloning

- Direct Access/Write Mode

- Protected Direct Access/Write Mode

- One-time programming (OTP) configuration

AGV RFID Tag Commands

- Proprietary command protocol

- Comprehensive error logging reports

- Support cascade commands

System Overview of HUAYUAN RFID AGV Tag Device

Chip Detailed Block Diagram

HDX ISO11784/5 ID Data Structure