Interview: An In-Depth Look at RFID Technology in the Laundry Industry

RFID laundry tags are an effective solution for the textile service industry, offering a low-cost, high-efficiency alternative to traditional methods. The industry, known for its labor-intensive and physically demanding processes, benefits from RFID technology by reducing textile loss, minimizing labor workload, and improving operational efficiency.

The durability of RFID technology makes it an increasingly popular choice for improving textile management in this complex industry. Guohua Tao, our Managing Director, provides further insights into the deployment of RFID tags in the laundry industry in an interview with Think WIOT.

1. Mr. Tao, why are laundry companies choosing to use RFID technology?

Tao: Companies in the laundry industry expect real results. This means achieving a great ROI. Only then will they be convinced to adopt RFID technology. Many have already seen the benefits that RFID generate.

In the laundry industry, RFID technology is used to improve efficiency, reduce costs, and minimize errors in managing textile assets. Traditional methods of counting and tracking textiles, especially in sectors like hospitality and healthcare, are labor-intensive and prone to mistakes due to the similarity of items. RFID enables quick and accurate inventory management without the need for direct line of sight, saving both labor and energy costs.

Large textile service companies like Elis in France are using RFID, for example.

These companies share the benefits that they receive from using RFID and encourage other companies and groups to use the technology.

2. What is important to consider when deploying RFID technology in industrial laundry applications?

Tao: The end users of industrial RFID laundry tags see the shared benefits of using the technology. RFID is always an accessory of an additional device that helps the IT system operate more efficiently and stably.

It is also important for both the end users – hotels, hospitals, and etc. – and textile service companies to make sure that the data in their respective IT systems match, in order to prevent disputes over costs.

With a mature IT infrastructure, RFID deployment, and a more standardized system of implementation see significant returns on investment in scale laundry groups. The durability and stability of a qualified RFID laundry tag is critical in the system, which should maintain good performance after hundreds cycles industrial laundry processes. All of our RFID laundry tags are mandatorily subjected to simulated hundreds of thousands times of rubbing and aging test on our self-created test equipment and our own washing and high temperature drying test equipment, simulate an environment that is more challenging than typical industrial laundering.

3. What about in China? Is RFID adoption on the rise there?

Tao: Yes. In fact, this year, the largest hotel management company in China, H World Group Limited, formerly known as the Huazhu Hotels Group, are seriously working towards the step-by-step implementation of RFID. The group has over a million rooms, and over 10,000 hotels.

The project is currently in its evaluation phase, and Huayuan is part of this process. Strict tests are currently being carried out to test the quality and reliability of RFID tags from different suppliers. By collecting big data based on these tests, the H World Group sees the quality, performance after 100 or 200 wash cycles, RSSI, and insights into sensitivity data. This big data is then analyzed from their servers.

As newcomers to the project, we are working closely with them on the technology side. In fact, before this year, we’ve had zero sales of RFID laundry tags in China. The reason for this is because our sole focus is on the international market. However, after seeing how serious H World Group was in implementing RFID on a professional level, I believed it was a good opportunity to cooperate.

The Group welcomed HUAYUAN as one of their supplier partners due to positive feedback from the big data analysis, and from our good reputation on the international market. We are the sole supplier from China for RFID laundry tags for this project.

In 2019, H World Group bought an entire German hotel group worth several billions of euros. However, the situation soon became drastic when the Covid pandemic hit three to four months later. Even now, after several years, the company has not yet managed to get a good balance. I am currently consulting them on a possible solution for this in terms of laundry management. This is a great example of globalization, especially between China and Europe.

4. Which industries have the highest demand for RFID-based laundry lifecycle tracking?

Tao: The highest demand for RFID-based laundry lifecycle tracking is seen in large textile service groups and companies that handle rental, laundry, and distribution of substantial textile assets. These groups can be divided into three sectors: hospitality, healthcare, and workwear. In the hospitality sector, including hotels, restaurants, and events, RFID helps manage linens and uniforms efficiently.

In healthcare, hospitals, nursing homes, and care facilities require precise tracking of textiles like bed linens and medical gowns to maintain hygiene standards. The workwear sector also relies on RFID to track uniforms and protective clothing used in various industries.

The retail industry is also beginning to adopt RFID technology for laundry management. Although we do receive many inquiries from the market, we believe that very large companies and groups that deal with thousands of tons of laundry on a daily basis have the most to gain from RFID deployment. An RFID system is optimally used in a large system.

5. What makes RFID tags suitable for the demanding requirements of the laundry industry?

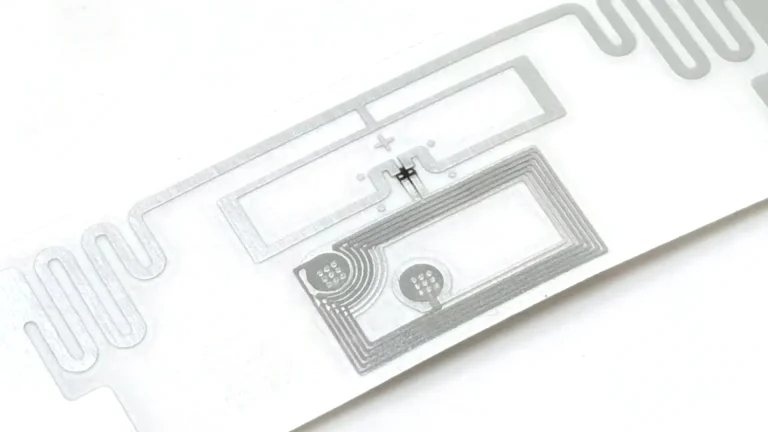

Tao: RFID tags used in the laundry industry must balance conflicting requirements: They need to be soft enough to embed seamlessly in textiles without being noticeable, yet robust enough to endure industrial laundry conditions. These conditions include exposure to high pressures of up to 60 bars, extreme temperatures, and harsh chemicals. Additionally, the tags must withstand at least 200 industrial wash cycles without compromising performance.

Our HLT Laundry RFID Tags, for example, also support GS1 standards, with compressed data and unique EPC codes derived from 10-digit GTINs, ensuring compatibility with global tracking systems. These features make RFID tags a reliable solution for textile tracking in industrial environments. Our tags are programmed with the GTIN EPC code by default, offering flexibility for customers who do not require customized encoding.

All of HLT laundry RFID tag are mandatorily subjected to hundreds of thousands times of rubbing and aging test on our self-created test equipment simulate a more challenging environment than typical industrial laundering to secure all of our tag components and integration are qualified.

6. Can you tell us more about the certifications of the RFID laundry tags?

Tao: Yes, of course. There are a multitude of regulations in the textile industry. All our RFID tags are compliant with all requirements. The laundry tags should not contain any harmful substances or materials, for example.

Our laundry tag certifications include: OEKO-TEX Standard 100, Eurofins Color, Fastness, SGS, ATP Certificate of EECC, POPS (Persistent Organic Pollutants), RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and PFAS (Per- and Polyfluoroalkyl Substances). These certifications prove the quality, safety, and reliability of our tags.

In January 2024, the REACH standard was updated to include an additional 200 or so materials. This shows how strict the certification and testing is, for harmful chemical substances within RFID tags for the textile industry.

7. What challenges must RFID tag manufacturers overcome when developing RFID tags for the laundry sector?

Tao: Manufacturers must ensure the tags perform reliably in harsh industrial laundry environments. This requires rigorous design, aging tests, and mass production quality control to maintain performance and durability. The integration of chip modules, antenna design, and adhesives demands advanced technical expertise and continuous innovation.

Manufacturers also face supply chain complexities, requiring large inventories of raw materials to ensure timely delivery, especially for unplanned orders. During the COVID-19 pandemic, chip shortages caused significant disruptions in the laundry RFID market.

Additionally, the evaluation and approval process for new products or changes to existing products, can take six months to two years, especially in markets like Germany and France. Any weaknesses in design or performance could result in substantial losses for textile service clients, making meticulous testing and customer approvals critical. We happy to see our HLT RFID laundry tag have no issued complain from all of our delivery yet.