RFID Case Study: UNIQLO Global Stores Applied RFID Tags

As a leading RFID tag manufacturer, HUAYUAN focuses on producing RFID tags for various industries, including retail, logistics, and apparel. This case study discusses the successful application of RFID technology in UNIQLO’s global stores, emphasizing the role of RFID tags in enhancing operational efficiency and customer experience. While RFID systems involve multiple components like readers, software, and integration, HUAYUAN’s expertise lies in providing the RFID tags themselves, which are a critical part of these advanced retail solutions.

RFID Technology for UNIQLO’s Global Stores

In 2017, Japanese fast fashion giant and UNIQLO parent company Fast Retailing group announced that it will be applied RFID tags in 3,000 stores worldwide within in one year, included 2,000 UNIQLO outlets stores.

UNIQLO is the first Japanese retailer to use RFID tags for apparel in worldwide, but its competitor H & M has introduced RFID technology in 2014; Zara deployed RFID systems in 2017 and has 2,200 retail stores and logistics centers worldwide. Complete the installation of RFID system. Coupled with the sister brand GU’s RFID attempts, the market favorably, these series of cases strongly accelerate the RFID tag application of UNIQLO global stores.

At present, UNIQLO’s RFID reform is in full swing. Featured applications may refer to Fast Retailing’s various brand stores in Yokohama, including smart devices such as RFID hang tags, RFID fitting mirrors, RFID shopping carts, and RFID self-checkout.

01 UNIQLO RFID Apparel Tag

Compared with bar codes that require manual operation,RFID tags can automatically read information wirelessly, further saving more labor and inventory costs. RFID tags can also collect specific information such as volume, model and color in a timely and accurate manner.

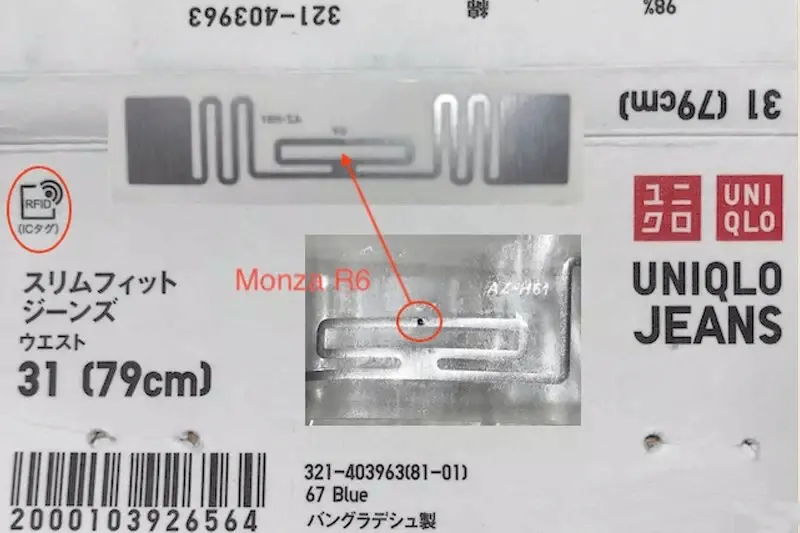

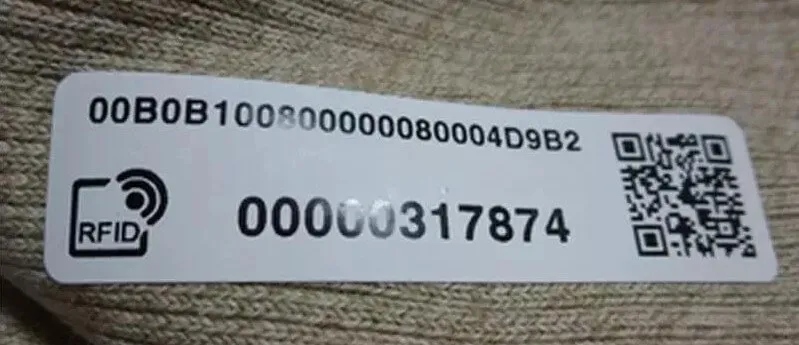

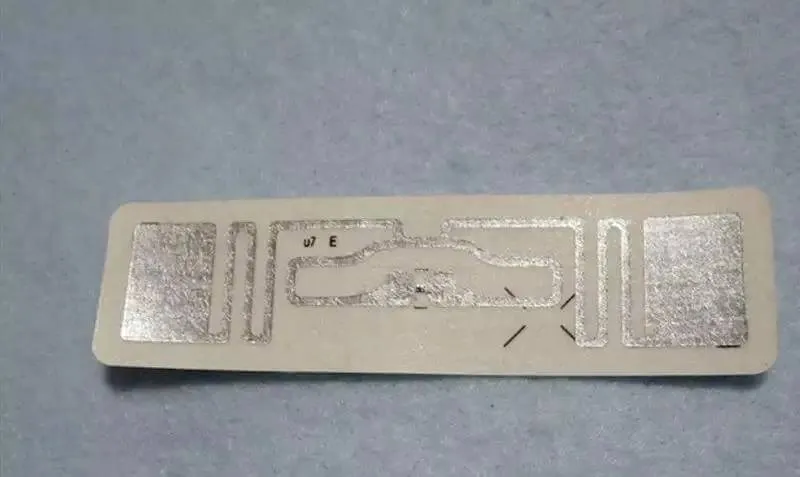

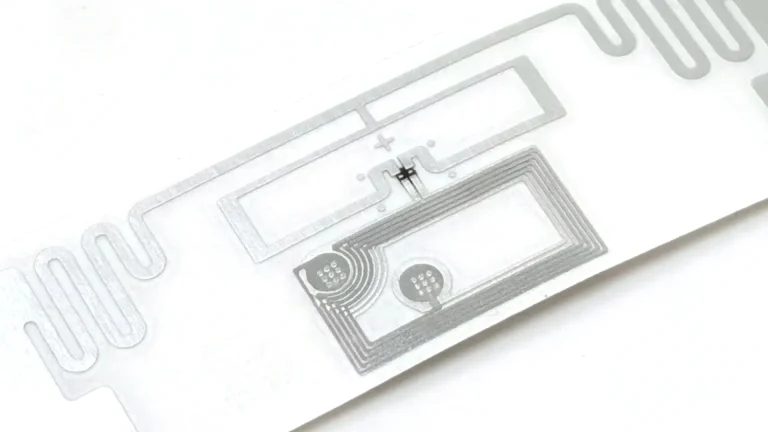

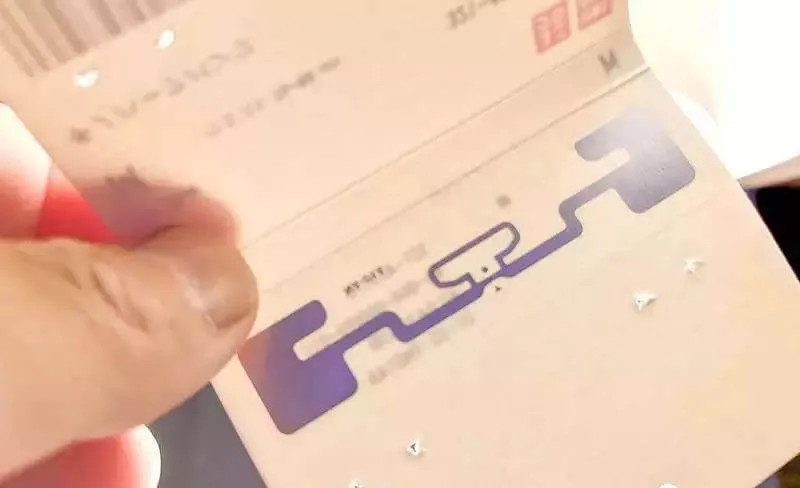

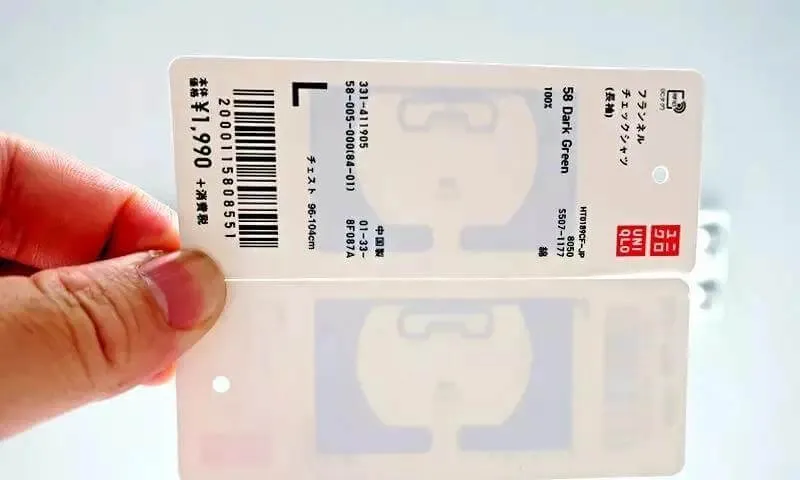

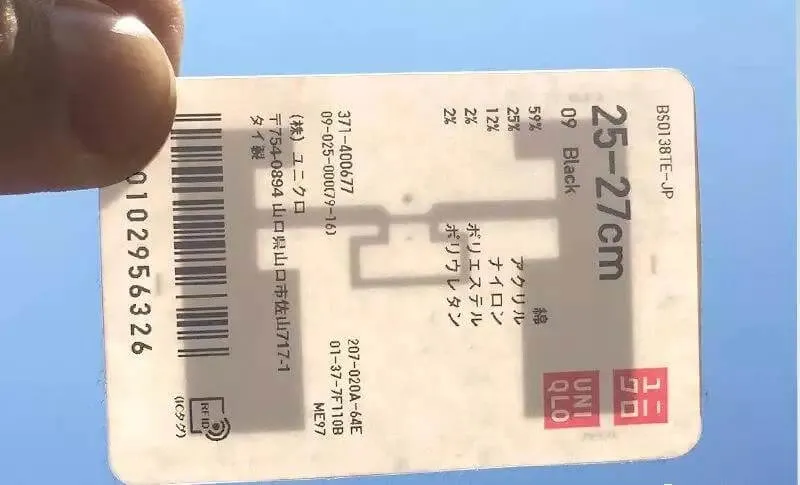

UNIQLO RFID tags are embedded with UHF RFID inlays. Based on the size difference, UNIQLO uses a variety of UHF RFID tags. Here are just three forms.

Slim UHF Tag

Omnidirectional RFID Label

Good directional RFID label

In order to attract customers’ attention to RFID, UNIQLO also made a small reminder on the RFID tag. Needless to say, this did arouse the curiosity of customers, and even caused a big discussion among UNIQLO fans. Some curious people also dismantled UNIQLO RFID tags to find out.

02 RFID UNIQLO’s Smart Store

When you come to the door of the store, you can’t start seeing the dazzling array of clothes. One piece of fitting makes you exhaust and hesitant. At this time, the magic mirror placed in the store will help you try on it.

- RFID Smart Shopping Guide

Just standing in front of the screen and swiping gently will help you choose clothes, try on clothes, and recommend a variety of collocations. If the store is small in size and cannot display all the products, at this time, the cloud shelf can present a large number of commodities that are not placed for you to choose. Select the product and scan the code with one click to place the order, and the fastest delivery will be in your hands. The role played by rfid UHF tags cannot be underestimated.

Meanwhile, customers can put their hands on the head to view the buyer’s comments, thereby helping themselves to judge the cost-effectiveness of the clothes.

GU had also innovated the RFID shopping cart, which is also a pretty cool existence.

After the customer selected the clothes of interest, they can put the clothes RFID tag on the RFID device of the shopping cart, and then the device will immediately display the product color, inventory status, and other sizes.

For GU and UNIQLO, this also greatly reduces the cost burden of shopping guides.

- RFID Self Checkout

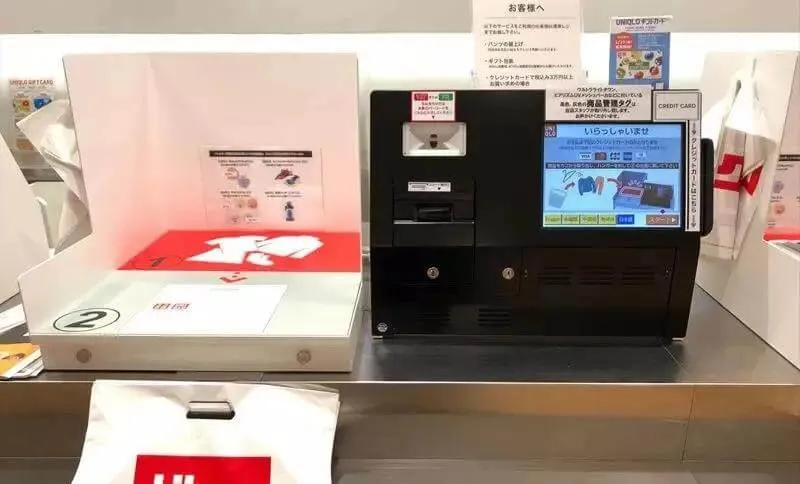

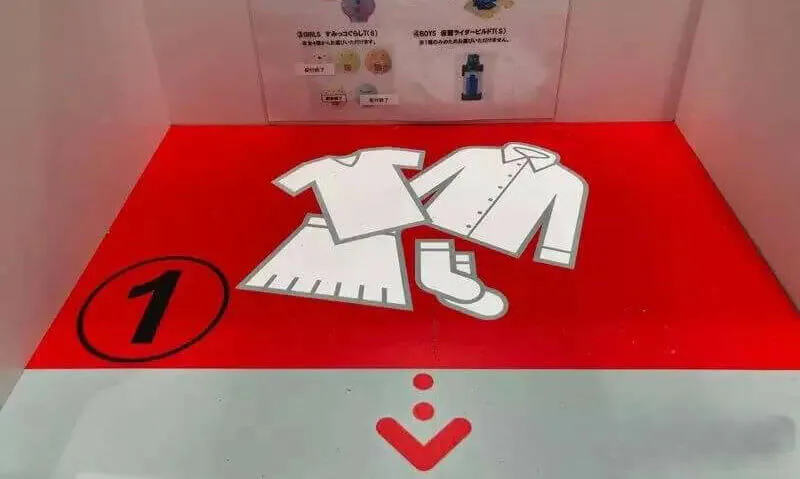

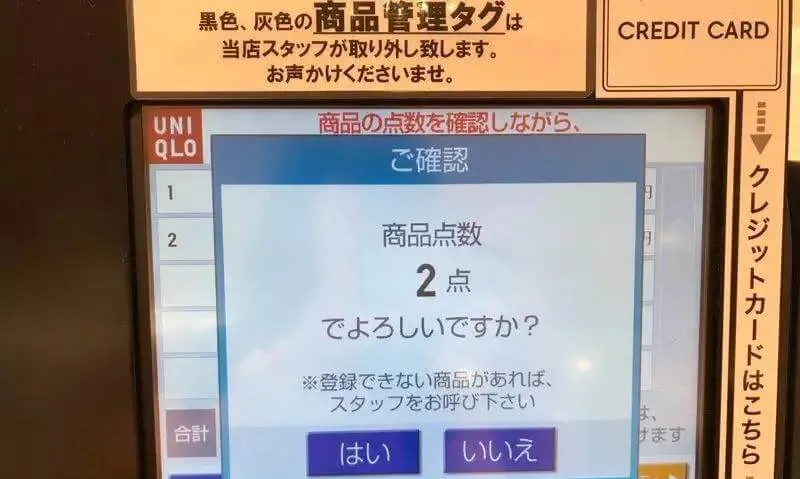

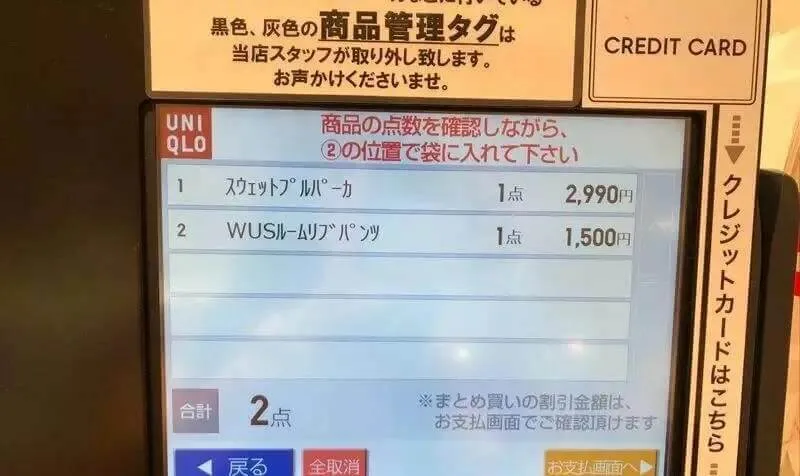

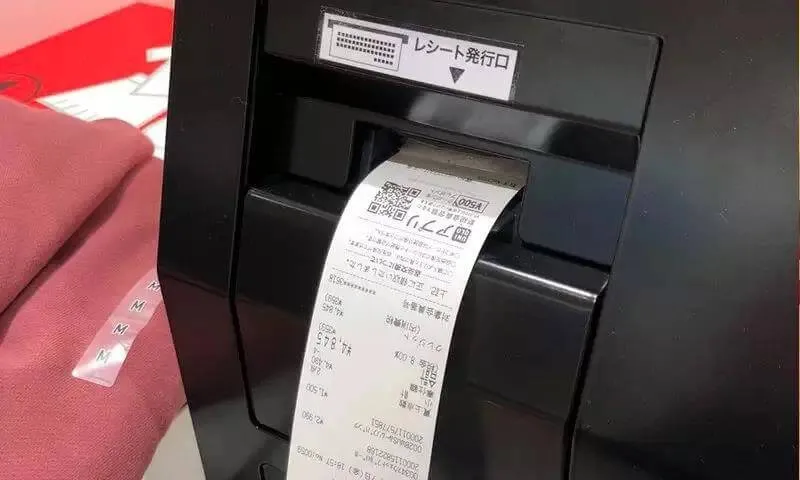

In addition, UNIQLO had also launched an RFID self-checkout counter. After the customer completes the shopping, the clothes on the shopping cart are placed on the RFID self-checkout machine, and the self-checkout machine will scan and give out the bill at one time, then the consumer can swipe the code to pay, and the whole process of self-service is without manual. The use of RFID self-checkout system can not only save the time of payment and inventory management, but also ensure that the company can quickly increase the output of hot products. And it can shorten the checkout time, ensure that the goods are in stock and provide other benefits.

UNIQLO RFID Self-Checkout Counter

Provide Membership Information for Points

Commodity Placement Table

RFID Counts Clothes

Display Clothes Price

Self-service Payment Provides Receipt Form

Lots of UNIQLO fans expressed their support and approval for the self-checkout counter, believing that this settlement method greatly reduced their shopping time and increased shopping efficiency. For UNIQLO, this application reduces the cash register labor costs and improves the accuracy of sales data.

In addition to reducing the manual burden on shopping guides, cash register settlement and other levels, RFID also reduces the burden on UNIQLO’s storage and data levels.

03 UNIQLO’s RFID Storage Management

Under the trend of fast fashion, whether fashion can really “fast up”, the efficiency of logistics warehousing operations is very critical. Especially for chain companies, once the efficiency of the logistics system drops, the operation of the entire company will be exposed to risks. Inventory backlog is a common problem in the retail industry. Ordinary stores are solving this problem by means of discounted sales. Using RFID information technology (forecasting demand), you can use data analysis to provide products that consumers really need, from the source to solve this problem.

RFID tags can automatically transfer information indefinitely, saving labor costs in inventory management, and more accurately obtain specific information about commodities such as transaction volume, model, color, size, etc., so that the inventory system can be updated in real time.

For example, if a certain item is sold out, you can quickly make a decision to replenish or reproduce it. The time required for electronic label inspection products is only 10% of the current commonly used inventory management system in the industry.

UNIQLO’s initial introduction of RFID tags is also considering this. At present, UNIQLO has applied RFID to its warehouse management.

According to related reports, UNIQLO attached RFID tags to all products and combined with automated material handling equipment. After establishing an automated warehouse, the number of warehouse personnel was reduced from about 100 to 10, saving 90% of labor costs. At the same time, UNIQLO’s production efficiency has increased by 80 times, shipment productivity has increased by 19 times, storage efficiency has increased by 3 times, personnel training costs have been reduced by 80%, and the accuracy of RFID automatic detection has been 100%.

In the Double 11 shopping carnival in 2018, UNIQLO achieved sales of $ 1 billion in one minute. And relying on its excellent automated inventory system, UNIQLO enables customers to pick up goods in offline stores within 24 hours.

04 Future Development Trend of RFID Technology

For China’s RFID industry, 2020 is an important development node. This special crisis, which has continued for several months since the beginning of 2020, has continued to increase the demand for RFID in some scenarios, such as unmanned convenience stores, self-checkout, medical products, and wearable devices.

Under special circumstances, in order to avoid unnecessary contact between people, “contactless shopping”, “contactless distribution” and other modes are popular. However, these “contactless” modes are indispensable to the support of RFID technology. For example, unmanned convenience stores need the function of RFID electronic tags to realize their characteristics and bring shopping convenience to customers. Therefore, the combination of RFID and “contactless” mode is getting closer.

At the same time, with UNIQLO’s widespread deployment of FRID label in 3000 stores around the world, the continuous evolution and development of high-tech technologies such as smart shopping and smart stores, I believe that in the near future, RFID technology will be more and more people Known and more comprehensively popularized.

05 HUAYUAN RFID Clothing Tags

HUAYUAN is an RFID tag manufacturer with millions of tags production capacity each month, If you need more information about RFID apparel tag labels, please contact our sales team.