UHF-RFID-Tag für Fahrzeugveredelung und -versand

Die RFID-Technologie kommt in vielen Branchen zum Einsatz, und ihr Einsatz nimmt weiter zu. Ein Beispiel dafür ist die Automobilbranchein denen Unternehmen RFID in vielen Bereichen ihrer Produktions- und Vertriebsketten einsetzen. RFID hat einen besonderen Wert für die Automobilhersteller und -händler.

Die Nachfrage nach einer schnellen, qualitativ hochwertigen, umweltfreundlichen und effizienten Produktion nimmt in der Automobilindustrie weiter zu. Die RFID-Technologie bietet eine viel höhere Geschwindigkeit als Barcodes, da die meisten Produktionsschritte automatisiert werden können. Darüber hinaus gewährleistet die Einführung von RFID in der Automobilproduktion eine vollständige Transparenz des Materialverbrauchs, der fertigen Waren und ihres Standorts und hilft bei der Verwaltung ein- und ausgehender Sendungen.

Fahrzeugverfolgung bei Audi mit UHF-RFID-Tag

Die verstreuten Parkplätze und die wechselnde Infrastruktur an den Audi-Produktionsstandorten führen zu hohen Kosten für die Fahrzeugsuche. Die Fahrzeuge waren nicht den Produktionslinien zugeordnet. Das manuelle System verlangte von den Fahrern Papierkram und standortspezifisches Scannen von Barcodes. Diese Methode ist arbeitsintensiv und bietet nur einen begrenzten Einblick in das Management des Fertigungs- und Versandprozesses.

Audi hat sich nun für ein einheitliches Fahrzeugverfolgungskonzept für die Veredelungs- und Versandprozesse an allen Produktionsstandorten entschieden. Die produzierten Fahrzeuge werden auf dem Werksparkplatz und im montierten Produktionsbereich per RFID erfasst.

Zur Identifizierung erhält jedes Fahrzeug nach der Montage einen UHF-RFID-Tag an der Innenseite des vorderen Stoßfängers. Der passive RFID-Tag wird am Fließband mit einer Fahrzeug-Identifizierungsnummer (VIN) und einer weiteren, an der Montagestation verwendeten ID-Nummer beschrieben.

Beim Durchlaufen des RFID-Lesegeräts wird die ID-Nummer des entsprechenden Fahrzeugtransponders erfasst. Die ID wird zusammen mit den Daten zur Richtungserkennung an das Back-End-System übermittelt. Die auf jedem Lesegerät installierte RFID-Software interpretiert die Leseereignisse, filtert überflüssige Daten oder falsche Messwerte heraus und leitet die relevanten Informationen an das IT-System weiter. Gleichzeitig verwaltet und überwacht die RFID-Software den Status der RFID-Hardware an den installierten Lesepunkten.

Die RFID-Erfassung erfolgt auf dem Werksparkplatz und in den Produktionsbereichen der Montage. Beim Einparken hat der Fahrer außerdem die Möglichkeit, den Transponder des Fahrzeugs und den Parkplatz mit einem Handlesegerät manuell zu erfassen oder die Daten zu korrigieren. An einigen Produktionsstandorten können GPS-Koordinaten erfasst werden, um den genauen Standort des Fahrzeugs an das IT-System zu melden.

UHF-RFID für KIA Fahrzeugveredelung und -versand

Der britische Logistikdienstleister Paragon Automotive setzt die passiven UHF-RFID-Tags von Smartrac ein, um den Eingang, die Sortierung, die Lagerung und den Versand von Fahrzeugen in der Werkstatt und in Außenlagern zu verfolgen.

Das Wachstum des Neuwagenmarktes hat die Automobilhersteller und ihre Logistikdienstleister unter Druck gesetzt, die Fahrzeuge schneller zu den Einzelhandelsstandorten zu bringen. Die manuelle Verfolgung des Standorts all dieser Fahrzeuge ist ein zeitaufwändiger Prozess. Bei einer Bestandsprüfung von 20.000 Fahrzeugen war ein Team von 20 Mitarbeitern ein ganzes Wochenende lang damit beschäftigt, den Standort jedes Fahrzeugs zu ermitteln. Diese neuen Fahrzeuge waren nicht mit Nummernschildern ausgestattet, so dass sie optisch schwer zu identifizieren waren.

Außerdem mussten die Bediener in der Lage sein, die Fahrzeuge zu lokalisieren, während sie den Aufbereitungsprozess durchliefen, was oft viel Arbeit bei der manuellen Eingabe der Standorte in das System bedeutete, damit die Informationen später zum Auffinden der Fahrzeuge verwendet werden konnten. Jedes Fahrzeug wird auf einem Platz gelagert, der durch eine bestimmte Zeile und einen bestimmten Stellplatz gekennzeichnet ist. Die Adresse könnte z. B. "Ankünfte, Reihe AA, Stellplatz 28" lauten. Jedes Mal, wenn ein Bediener ein Fahrzeug bewegt, erfasst er oder sie manuell den neuen Standort und die Fahrzeugidentifikationsnummer (VIN) des Fahrzeugs mit einem robusten Android-basierten Handheld-Gerät.

Die RFID-Technologie wird eingesetzt, um die Standortdaten der eingelagerten Fahrzeuge zu bestätigen - zum Beispiel, um festzustellen, ob ein bestimmtes Fahrzeug nicht in einem bestimmten Bereich, einer bestimmten Reihe und einem bestimmten Intervall geparkt ist. Der Einsatz von RFID bedeutet, dass wir eine zweite Methode haben, um jede Einheit zu lokalisieren, falls ein Bediener den Standort nicht korrekt erfasst. das RFID-System bestätigt diese Daten. Darüber hinaus ermöglicht RFID den Nutzern in der Werkstatt, die Fahrzeuge über Handlesegeräte zu identifizieren, ohne die letzten acht Ziffern der Fahrgestellnummer eingeben zu müssen.

Nachdem die Fahrzeuge vom Schiff entladen wurden, werden UHF-Tags an der Innenseite der hinteren Fahrerscheibe jedes Fahrzeugs angebracht, und die kodierte ID-Nummer des Tags wird mit der Fahrgestellnummer des Fahrzeugs verknüpft. Die Kombination von RFID-Lesegeräten, die an jedem Standort installiert sind, mit der IT-Plattform und dem RFID-Managementsystem stellt sicher, dass bei der Lagerung, dem Abschluss der Arbeiten, der Inspektion oder dem Versand keine Fehler gemacht werden, und spart den Mitarbeitern Zeit, die sie sonst für die manuelle Inventarisierung oder die Suche nach bestimmten Fahrzeugen im Werk aufwenden müssten.

Vorteile

- Verbesserte Sichtbarkeit des Fahrzeugmanagementprozesses.

- Der Zeitaufwand für die Suche nach gesuchten Fahrzeugen wird reduziert.

- Die vorhandenen Ressourcen und Parkplätze werden optimal genutzt.

- Die Durchlaufzeit wird durch den Wegfall des manuellen Scanvorgangs verkürzt.

- Verarbeitungs- und Transportabläufe werden effizient gestaltet.

- Reduziert den Zeit- und Kostenaufwand für bestehende Kontrollprozesse.

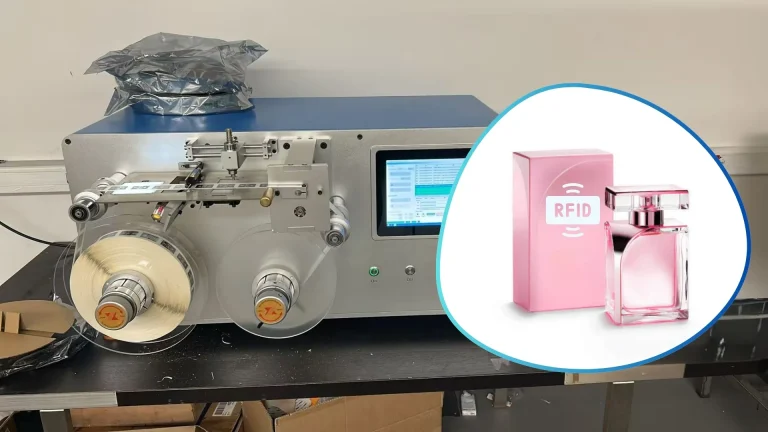

HUAYUAN Passiver UHF-RFID-Tag für Fahrzeugveredelung und -versand

HUAYUAN liefert seit Jahren FAW-Gruppe (Chinas Nr. 1 Automobilwerk, das High-End-Autos produziert) mit Fahrzeug-Tracking-RFID-Tags für 2 Jahre, und im Jahr 2021, lieferten wir FAW mit 1,8 Millionen RFID-Tags. HUAYUAN in der Entwicklung dieser Tag ist voll und ganz als die Auto-Stoßstange auf die RFID-Frequenz-Interferenz, die Produktion von hochwertigen elektronischen Identifikation. HUAYUAN liefert auch RFID-Windschutzscheiben-Etiketten, RFID-Etiketten für Auto-Kunststoffteile und Autositze sowie mehr als zehn verschiedene Etiketten an drei andere große inländische Autofabriken für das automatisierte Produktionsmanagement, die Verwaltung von Bestandsteilen und die Verwaltung der Fahrzeugveredelung und des Versands.

Wenn Sie mehr über RFID-Etiketten für die Fahrzeugveredelung und den Versand erfahren möchten, wenden Sie sich bitte an das HUAYUAN-Team, um eine kostenlose Beratung zu erhalten. HUAYUAN ist ein professioneller Hersteller von RFID-Tagsdie alle Arten von passiven RFID-Etiketten, aber keine RFID-Systeme anbieten.