Verbessertes Palettenmanagement mit RFID-Technologie

Warum die RFID-Technologie in die Palettenverwaltung integrieren?

Viele Unternehmen leasen Paletten, Kisten, Rollkäfige, Umschlagboxen und andere Logistikbehälter, um die Kosten für die Unterhaltung ihres eigenen Palettenparks zu senken. Aufgrund der Vielfalt der Produktmaterialien und des zunehmenden Umfangs von Logistik und Vertrieb werden jedoch immer mehr Logistikumschlagboxen und andere Behälter verwendet, und das Phänomen des Verlusts von Umschlagboxen hat ebenfalls zugenommen, was zu immer höheren Verwaltungskosten führt. Die Verwaltung der Rückgabe dieser Gegenstände hat sich für die Palettenanbieter oft als schwierig erwiesen.

Die RFID-Technologie wird zunehmend mit Palettenverfolgungssystemen kombiniert, da sie eine genaue und automatische Datenerfassung in Echtzeit ermöglicht. Herkömmliche Barcodesysteme sind zwar effektiv, erfordern aber ein Scannen mit Sichtkontakt und manuelle Handhabung, was zeitaufwändig und fehleranfällig sein kann. Im Gegensatz dazu können RFID-Etiketten aus der Ferne gelesen werden, erfordern keine direkte Sichtverbindung und können gleichzeitig Daten von mehreren Etiketten an ein RFID-Lesegerät übertragen.

Durch die Integration der RFID-Technologie in die Palettenverfolgung erhalten Unternehmen einen Echtzeit-Überblick über ihren Bestand, senken die Arbeitskosten, minimieren menschliche Fehler und verbessern die Effizienz der gesamten Lieferkette. Dies ist besonders wertvoll in Branchen, in denen Paletten und Container häufig zwischen verschiedenen Standorten hin- und herbewegt werden, wie z. B. Palettenleasing, industrielle Produktionskontrolle, Automobil- und Lebensmittelindustrie.

Die Vorteile des Einsatzes von RFID-Technologie für das Palettenmanagement

- Verbesserte Bestandsgenauigkeit und Sichtbarkeit: Die RFID-Technologie ermöglicht die Verfolgung von Paletten in Echtzeit und liefert genaue und aktuelle Informationen über die Lagerbestände. Dies hilft Unternehmen, Überbestände und Fehlbestände zu reduzieren, die Bestandsverwaltung zu optimieren und rechtzeitige Lieferungen zu gewährleisten.

- Verbesserte betriebliche Effizienz: RFID-Systeme automatisieren den Verfolgungsprozess und verringern den Bedarf an manueller Arbeit und menschlichem Eingreifen. Diese Automatisierung beschleunigt die Abläufe, senkt die Arbeitskosten und minimiert das Risiko menschlicher Fehler, was zu einer höheren Gesamtproduktivität führt.

- Schnellere Datenerfassung und -verarbeitung: Im Gegensatz zu Strichcodes, die einzeln gescannt werden müssen, können RFID-Lesegeräte Daten von mehreren Etiketten gleichzeitig erfassen. Dies beschleunigt den Prozess der Datenerfassung und reduziert den Zeitaufwand für Bestandskontrollen und Audits.

- Verbesserte Rückverfolgbarkeit und Compliance: Mit Hilfe der RFID-Technologie können Unternehmen die Warenbewegungen über die gesamte Lieferkette hinweg verfolgen, was die Rückverfolgbarkeit verbessert und ihnen hilft, die gesetzlichen Vorschriften einzuhalten. Dies ist besonders nützlich in Branchen wie der Pharma-, Lebensmittel- und Getränkeindustrie, in denen die Rückverfolgbarkeit für die Sicherheit und Qualitätskontrolle entscheidend ist.

Implementierung von RFID für die Palettenverfolgung

Die Implementierung der RFID-Technologie für die Palettenverfolgung umfasst mehrere Schritte:

- Bewertung und Planung: Der erste Schritt besteht darin, eine gründliche Bewertung der bestehenden Lieferkettenprozesse vorzunehmen, um die Bereiche zu ermitteln, in denen RFID am vorteilhaftesten sein kann. Dazu müssen die Art der zu verfolgenden Waren, das Umfeld, in dem die Technologie eingesetzt werden soll, und die spezifischen Anforderungen an die Datenerfassung und -verwaltung analysiert werden.

- Tag-Auswahl: Die Wahl des richtigen RFID-Etikettentyps ist entscheidend für eine erfolgreiche Implementierung. Die Tags müssen für die zu verfolgenden Paletten und Behälter geeignet sein, wobei Faktoren wie das Material der Paletten, die Umgebungsbedingungen und der erforderliche Lesebereich zu berücksichtigen sind.

- Einrichtung von Lesegeräten und Infrastruktur: Die Installation von RFID-Lesegeräten an den wichtigsten Punkten der Lieferkette, z. B. an Ein- und Ausgängen, Lagerbereichen und Transportfahrzeugen, ist für die Datenerfassung unerlässlich. Die Infrastruktur sollte so konzipiert sein, dass eine maximale Abdeckung und Datengenauigkeit gewährleistet ist.

- Software-Integration: Um einen nahtlosen Datenfluss und Echtzeittransparenz zu gewährleisten, muss das RFID-System in die bestehende Bestandsverwaltungs- und ERP-Software (Enterprise Resource Planning) integriert werden. Diese Integration ermöglicht es Unternehmen, ihre Bestände effektiver zu verwalten und datengestützte Entscheidungen zu treffen.

- Schulung und Prüfung: Die Schulung der Mitarbeiter im Umgang mit der neuen Technologie und die Durchführung umfassender Tests zur Ermittlung potenzieller Probleme sind entscheidend für eine erfolgreiche Einführung. Durch die Tests wird sichergestellt, dass das System effektiv funktioniert und die spezifischen Anforderungen der Organisation erfüllt.

Herausforderungen und Beschränkungen von RFID im Palettenmanagement

Die RFID-Technologie bietet zwar zahlreiche Vorteile, doch gibt es auch einige Herausforderungen und Einschränkungen zu beachten:

- Hohe Anfangskosten: Die Kosten für RFID-Etiketten, Lesegeräte und Infrastruktur können im Vergleich zu herkömmlichen Ortungsmethoden relativ hoch sein, insbesondere für kleine und mittlere Unternehmen. Dies kann dazu führen, dass die Anfangsinvestition ein erhebliches Hindernis für die Einführung darstellt.

- Probleme mit Interferenzen: RFID-Signale können durch verschiedene Faktoren beeinträchtigt werden, z. B. durch Metallgegenstände, Flüssigkeiten und Umgebungsbedingungen, die ihre Wirksamkeit verringern können. Eine angemessene Planung und Prüfung ist erforderlich, um diese Interferenzen zu minimieren.

- Datenschutz und Sicherheitsbedenken: Da mit der RFID-Technologie Daten über große Entfernungen übertragen werden können, bestehen potenzielle Datenschutz- und Sicherheitsbedenken in Bezug auf einen unbefugten Datenzugriff. Es muss sichergestellt werden, dass das RFID-System sicher ist und den Datenschutzbestimmungen entspricht.

- Komplexität der Datenverwaltung: Die Einführung der RFID-Technologie erzeugt eine große Menge an Daten, deren Verwaltung und Analyse schwierig sein kann. Unternehmen müssen über robuste Datenverwaltungssysteme verfügen, um diese Daten effektiv verwalten zu können.

- Begrenzte Lesereichweite von passiven RFID-Tags: Passive RFID-Tags haben im Vergleich zu aktiven Tags eine begrenzte Lesereichweite. Dies kann in Umgebungen, in denen eine Verfolgung über große Entfernungen erforderlich ist, eine Einschränkung darstellen.

Auswahl der richtigen RFID-Technologie

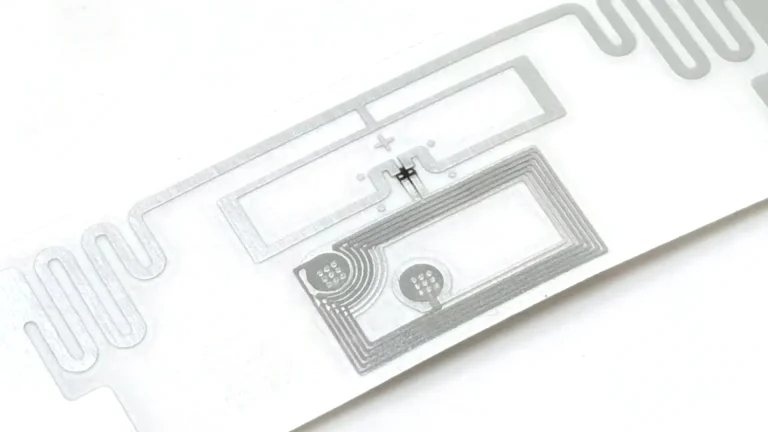

RFID-Etiketten werden je nach Art der Übertragung von Frequenzsignalen in zwei Typen unterteilt: aktive und passive.

Aktive RFID-Etiketten: Diese Tags haben eine eingebaute Batterie und ermöglichen eine große Lesereichweite, sind aber teurer. Sie werden hauptsächlich für Anwendungen verwendet, die eine Erkennung von wertvollen Gegenständen mit großer Reichweite erfordern.

Passive RFID-Etiketten: Diese Tags haben keine Batterie und sind im Allgemeinen preiswerter, aber ihre Lesedistanz und Speicherkapazität sind durch die Verfügbarkeit von Strom begrenzt. In Logistikanwendungen, bei denen der erforderliche Arbeitsabstand innerhalb von 2 Metern liegt und die Speicherkapazitäten moderat sind, sind passive RFID-Tags in der Regel die beste Wahl.

Zu den in Logistikanwendungen verwendeten RFID-Frequenzen gehören Hochfrequenz (HF) und Ultrahochfrequenz (UHF):

HF (Hochfrequenz): HF-Tags haben eine Lesedistanz von bis zu 1,5 Metern und eine starke Fähigkeit, Tags durch Objekte hindurch zu lesen.

UHF (Ultra-Hochfrequenz): UHF-Etiketten, insbesondere solche, die der RAIN-RFID-Technologie entsprechen (passive UHF-RFID, die den Normen GS1 EPC Class 1 Gen2 oder ISO 18000-63 entsprechen), bieten eine größere Lesedistanz von 3 bis 9 Metern, haben aber eine geringere Durchdringungsfähigkeit.

Für die Verwaltung von RFID-Etiketten auf Paletten und Umschlagkisten, bei denen die typische Lesedistanz etwa 2 Meter beträgt und ein Durchdringen von Objekten nicht erforderlich ist, sind UHF-Etiketten die richtige Wahl.

Arten von passiven RFID-Tags für die Palettenverwaltung

In Anbetracht der Arbeitsumgebung von Paletten empfiehlt HUAYUAN die Lieferung von UHF-RFID-Tags:

LogiFlex UHF-RFID-Palettenanhänger

LogiFlex UHF-RFID-Palettenetiketten sind laminierte PVC-Etiketten, die einfach mit Schrauben oder Klebstoff auf Kunststoffpaletten angebracht werden können und so gebaut sind, dass sie Stößen und allgemeinem Verschleiß standhalten. Der Hauptvorteil der LogiFlex-Tags sind ihre niedrigen Kosten, was sie zu einer ausgezeichneten Wahl für groß angelegte Anwendungen macht. Darüber hinaus können sie mit Logos, Barcodes und anderen Informationen in Farbe versehen werden, was eine vielseitige und kostengünstige Lösung für den Einsatz in Innenräumen oder im Freien darstellt.

Kunststoffgehäuse RFID-Tags

RFID-Etiketten mit Kunststoffgehäuse sind robust und eignen sich für Umgebungen, in denen sie mäßigen mechanischen Stößen oder Staub ausgesetzt sind. Diese Tags können mit Schrauben oder Klebstoff an Kunststoffbehältern befestigt werden und sind eine zuverlässige Option für die Verfolgung von Paletten und Behältern in Lagern oder industriellen Umgebungen. Obwohl sie teurer sind als PVC-Alternativen, bleiben RFID-Tags mit Kunststoffgehäuse erschwinglich und bieten ein gutes Gleichgewicht zwischen Kosten und Haltbarkeit.

Vielseitiger RFID-UHF-Tag

Die vielseitigen RFID-UHF-Tags sind preisgünstig und eignen sich gut für den Einsatz in Innenräumen, insbesondere für Anwendungen mit Metallkäfigen. Sie bieten ein ausgezeichnetes Gleichgewicht zwischen Kosten, Haltbarkeit und Funktionalität, was sie zu einer flexiblen Wahl für verschiedene industrielle Anwendungen macht.

PCB-RFID-Tags

PCB-RFID-Tags sind Premium-Tags, die für raue und anspruchsvolle Umgebungen entwickelt wurden. Sie eignen sich ideal für Anwendungen, bei denen eine überragende Haltbarkeit erforderlich ist, wie z. B. in Industrieanlagen mit extremen Bedingungen. Diese Tags bieten eine hervorragende Leistung in Umgebungen, die Chemikalien, Feuchtigkeit und erheblichen Temperaturschwankungen ausgesetzt sind, was sie zur bevorzugten Wahl für die anspruchsvollsten Einsatzszenarien macht.

Kontakt aufnehmen

Kontaktieren Sie uns noch heute, um mehr über die richtige RFID-Lösung für Ihr Unternehmen zu erfahren. Unser Expertenteam unterstützt Sie bei der Auswahl der besten Etiketten, der Implementierung der erforderlichen Infrastruktur und der nahtlosen Integration in Ihre bestehenden Systeme. Wir helfen Ihnen, Ihre Lieferkette intelligenter und effizienter zu gestalten.